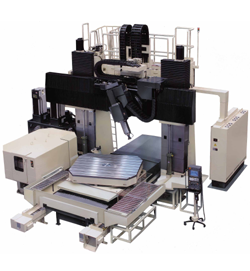

MP-2620(U)

· By using the exchange machining head, it is possible to perform combined machining such as milling and turning, and reduce the number of projects to shorten the time.

· It can be equipped with a 4-axis machining head (B-axis) and a 5-axis machining with a table (C-axis). It is suitable for machining complex parts with high added value like inclined · By using the exchange machining head, it is possible to perform combined machining such as milling and turning, and reduce the number of projects to shorten the time.

· It can be equipped with a 4-axis machining head (B-axis) and a 5-axis machining with a table (C-axis). It is suitable for machining complex parts with high added value like inclined flat or inclined holes.

· The linear shafts are driven by a dual motor, and the screw support portion is integrally formed with the bed to achieve high speed, high rigidity and high precision.

· Can be combined with ATC, AAC, AATC, AAI, APC to complete a variety of automatic processing needs.

|

Machine specifications |

|

|

|

MP-2620(U) |

|

X-Axis travel(longitudinal movement of rail) |

2500mm |

|

Y-Axis travel(crossing movement of spindle head) |

3400mm |

|

Z-Axis travel(vertical movement of spindle ram) |

800mm |

|

W-Axis travel(vertical movement of rail) |

1000mm (250mm/pitch, total 5 pitches) |

|

C-Axis travel(rotating movement of table) |

±360° (continuous) |

|

Height of door |

1785mm |

|

Distance between wall columns |

2600mm |

|

Diameter of table |

2000mm |

|

Table rotating speed |

2 ~ 250min-1 (2-speed shift) |

|

Section of spindle ram |

380mm × 380mm |

|

Spindle speed |

40 ~ 10000min-1 (2-speed shift) |

|

Type of tool shank |

BT-50 |

|

X, Y, Z-Axis positioning accuracy |

±0.007mm / 1000mm |

|

C-Axis indexing accuracy |

±5sec |

|

X, Y, Z-Axis repeatability |

±0.003mm |

|

C-Axis repeatability |

±3sec |